Robot Automation

ABCO is an industry leader in factory automation fueled by robots for manufacturing companies, leading to higher productivity, lower costs, increased worker safety, and improved quality.

ABCO Integrates Robots

ABCO has many years of experience in developing and implementing robotic systems. We can provide any form of robotics ranging from application evaluations and turnkey solutions to systems that specialize in flexible robotic work cells for accommodating short product life cycles and quick changeovers. Our project experience features robots that perform.

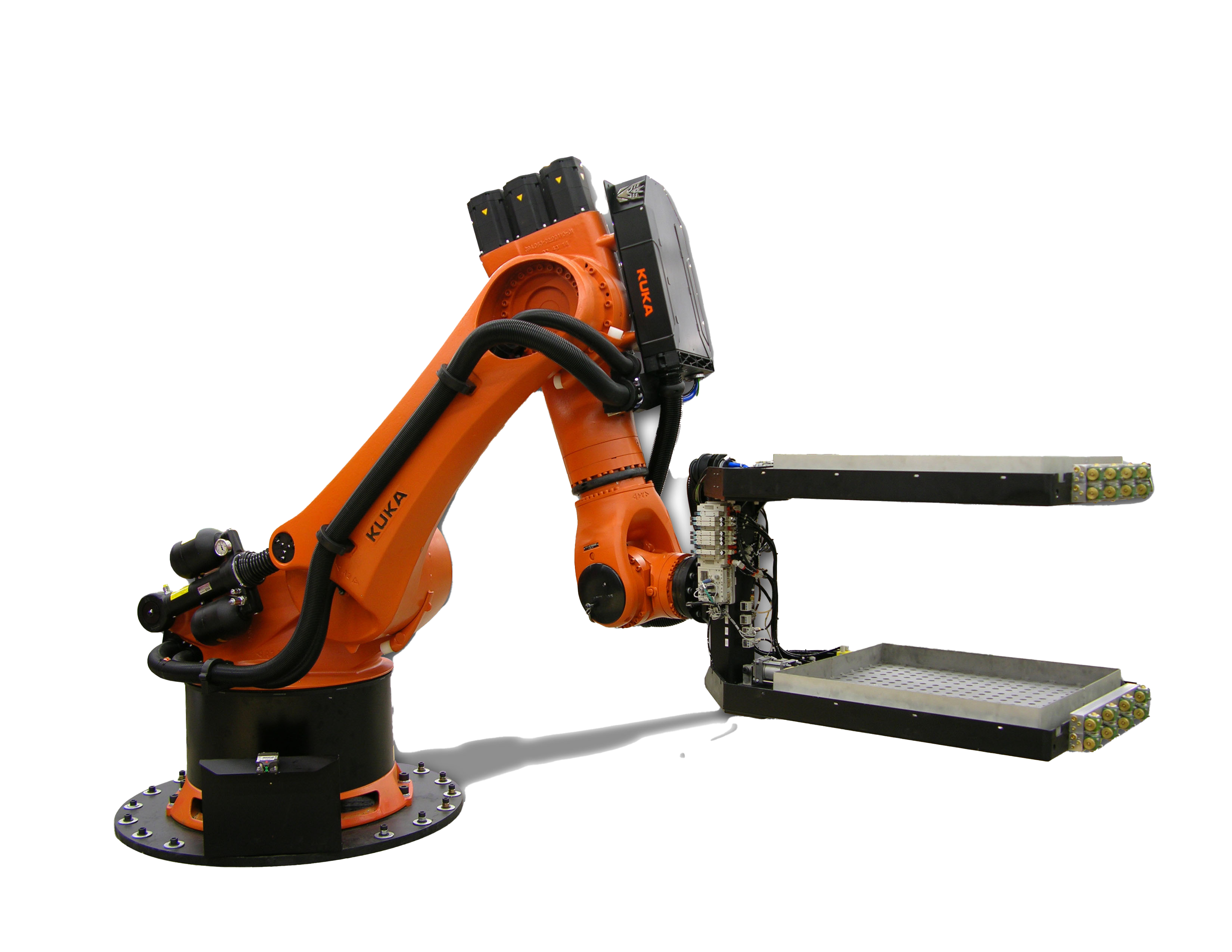

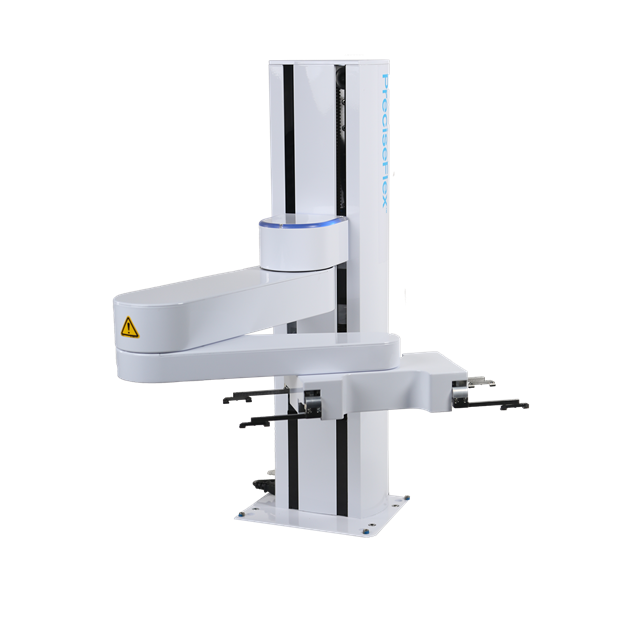

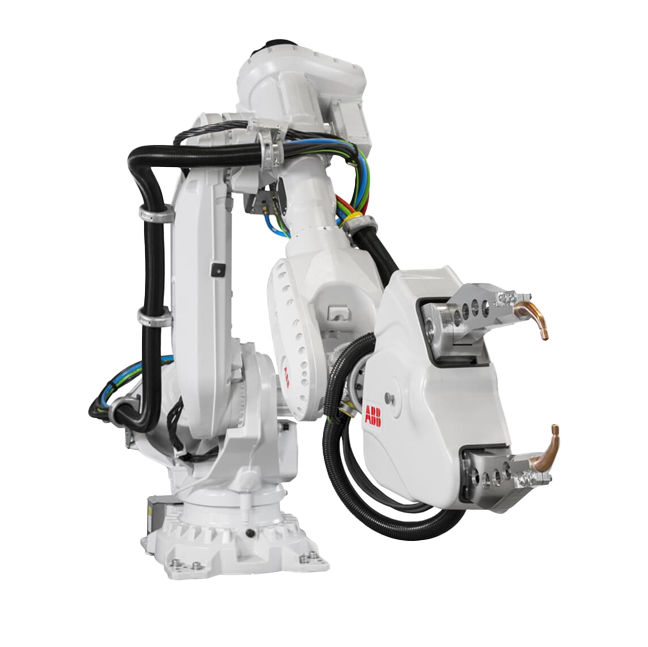

Industrial Robots

As an authorized Integrator for several of the largest Robot manufacturers, ABCO can offer many benefits to customers who have a preferred brand or are open to the best product that meets their specific needs. With decades of experience in the Food, Beverage, Logistics, Life Science, Healthcare and Agritech industries, ABCO can provide comprehensive, innovative, cost-effective solutions for you. There are multiple types of industrial robots available today. Click here to see a list of the robot types that ABCO Automation works with.

ABCO can design, specify, install and program your industrial robot solution.

Palletizing

Depalletizing

Packaging

Dispensing

Pick & Place

Case Packing

Machine Tending

Parts Assembly

Material Handling Systems

Custom Robotic Systems

.png)

.png)

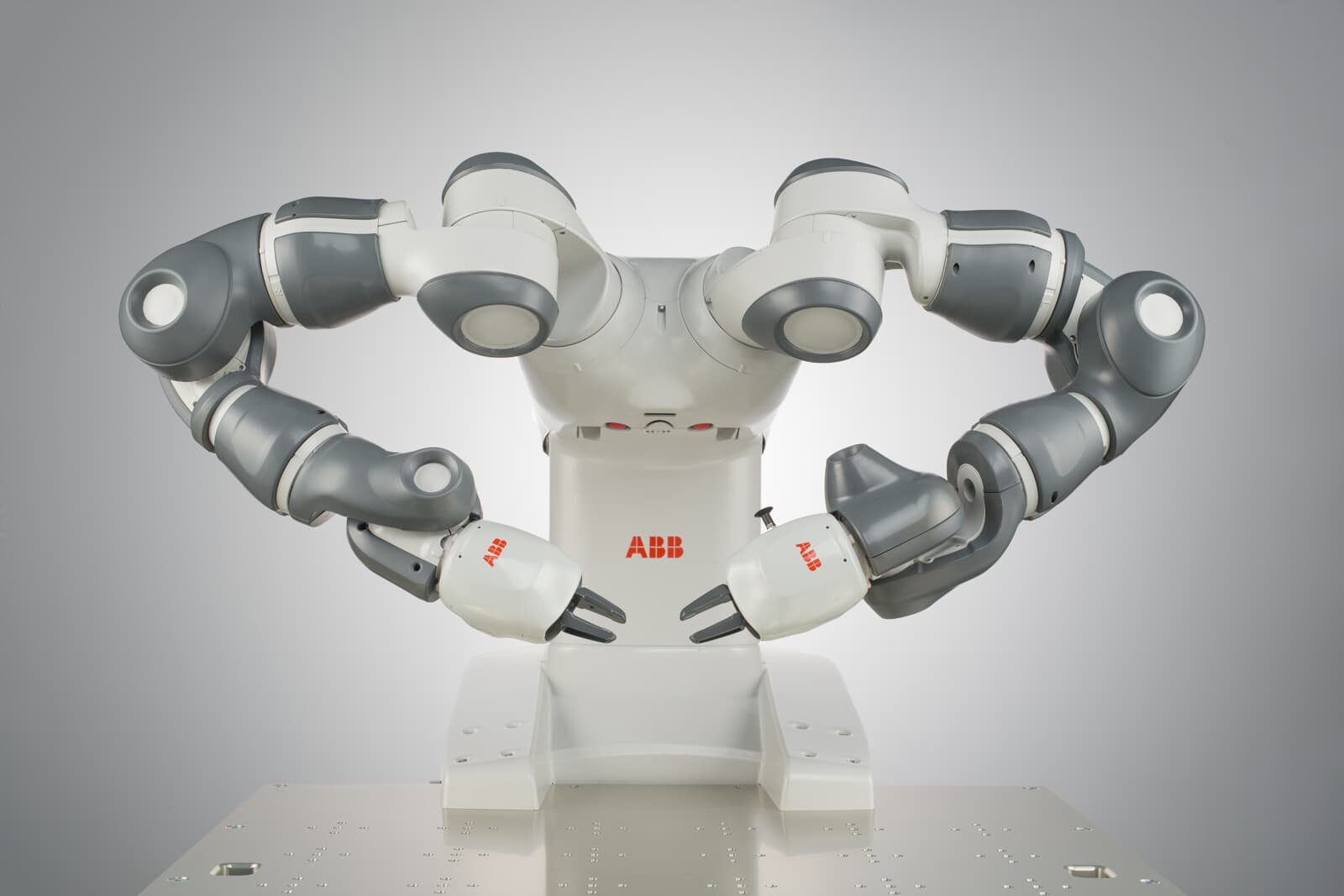

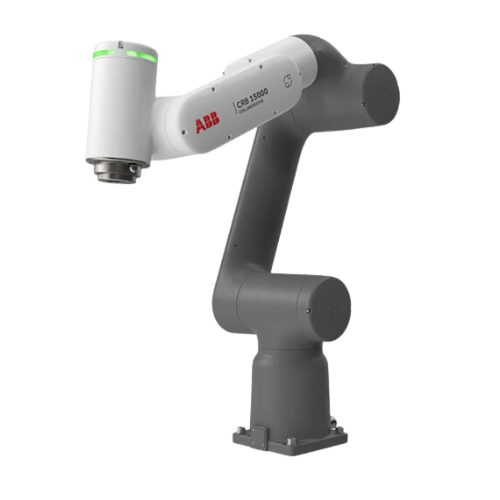

Cobots

Collaborative robots improve worker safety and morale by performing repetitive difficult tasks. The cobot solutions provided by ABCO are designed to meet the specific of each of application.

Cobots provided in ABCO’s value added solutions are dependable workers to supplement your existing team.

The cobots offered by ABCO work side by side with your staff or collaborate with them without the need for external safety devices (in accordance with risk assessment). ABCO designed, cobot solutions offer our customers a solution to labor shortages, more versatility and work ergonomics, improved safety, higher yield and reduced cost.

-2.png)

Benefits of Robot Automation

Factory automation fueled by robots provides many benefits to manufacturing companies, including higher productivity, lower costs, increased worker safety, and improved quality.

Lower Costs

With robotic systems, manufacturers can experience faster manufacturing times and increased efficiencies, which translates into producing more product in a timely manner. Over time those improved efficiencies lead to cost savings due to reduced waste, lower operational expenses, and decreased hands-on labor.

Employee Safety

Employees reap the bulk of the automation rewards. Robots can work in challenging environment, including hot, very cold, and very hazardous areas, so workers are to be exposed to any of those conditions. In addition, employees can be moved from performing tedious labor-intensive tasks to assignments that offer more engaging responsibilities.

Improved Quality

Additionally, manufacturers can see improved quality due to consistent product fabrication and quality control systems that use vision systems to continually check for defects.