Bag In Box Fillers

For over 40 years, ABCO Automation has been an industry leader in the design and manufacture of Bag-in-Box Fillers (BIB), including high-speed, semi-automatic, rotary, or custom machines. ABCO fillers are recognized around the world as the best bag-in-box liquid fillers available in the industry. Our throughput rates, accuracy, and reliability are second to none. ABCO has been building liquid filling equipment and bag-in-box machines since 1977 with installations in over 20 countries.

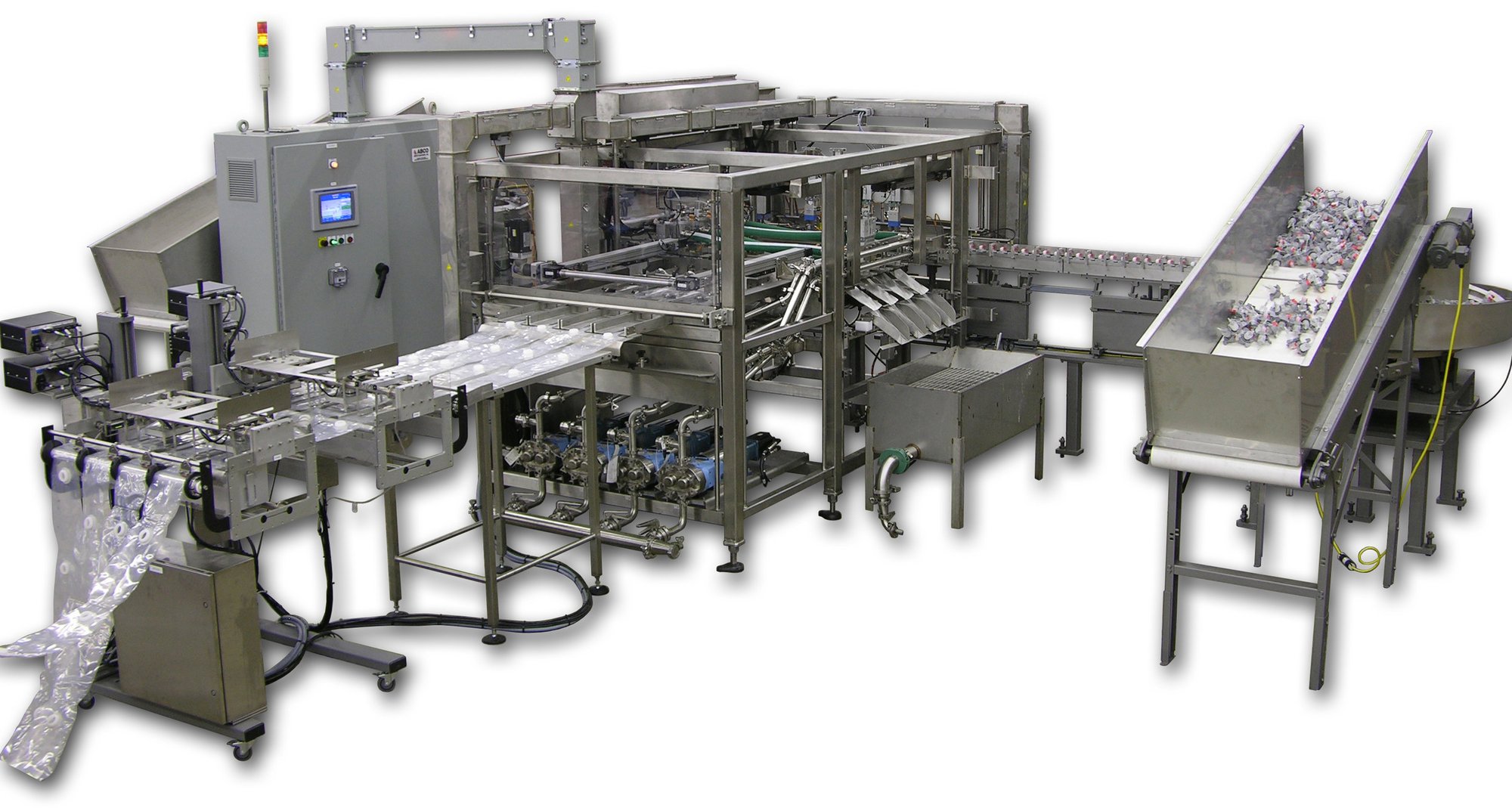

High Speed Fillers

ABCO manufactures fully automated high-speed fillers with the capability to fill up to 25 bags per minute. Two models are available, HS-2000 (single head) or HS-4000 (dual head). ABCO’s durable and reliable high-speed fillers can accommodate a broad range of bags, fitments and dispensers.

Wine / Spirits

Beverages

Soaps & Detergents

Petroleum

Automatic & Semi-Automatic Fillers

Filling equipment is the key component in a high-volume bag-in-box packaging line. ABCO fillers ensure that filling is not the weak link in the supply chain. Our systems are designed longevity and reliability and accommodate expected variations in the bags and fittings without jamming or stopping.

Features include:

Automated bag loader and unloader

“No-drip” valve

+/- 0.3% fill accuracy

Clean-in-place design

Fully programmable fill levels and rates

SS Construction

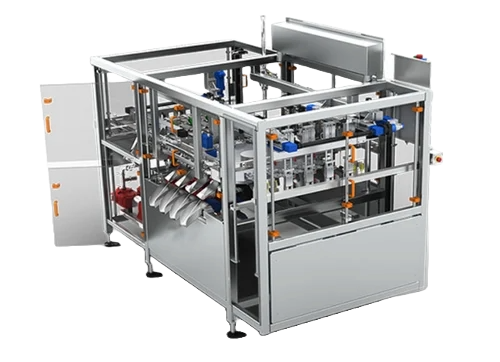

Rotary Fillers

ABCO’s durable and reliable rotary fillers are fully automatic machines that can accommodate a broad range of bags, fitments and dispensers. These fillers offer ease of use and flexibility for accurate filling, maximum product yield, rapid product changes, trending, rapid troubleshooting, and simplified operator training

Produce more with higher rates

Save money with accurate filling

Stay clean with no drip valves

Single cell or complete line

Custom Design BIB Fillers

ABCO can custom design and build filler systems to meet your specific filling needs. We work to become your trusted advisors and will work to fully understand your processes and business model. ABCO’s account management and engineering teams will work closely with you to define the custom bag-in-box filler requirements, develop a concept and provide a proposal for your approval. There will be no grey areas and we will deliver filling solutions to meet your unique needs.

ABCO BIB BENEFITS

- Increase productivity with enhanced efficiency rates

- Maximize cost savings through precise filling

- Maintain seamless operations with automated processes

- Optimize time management with user-friendly features

- Ensure cleanliness with leak-proof valve systems

ABCO BIB OPTIONS

- Nitrogen topoff

- Case erector / bottom case sealer

- Top case sealer

- Case coder

- Product and case labeling

- Automated palletizer with stretch wrapping

- CE and UL listed panels

ABCO BIB FEATURES

- Automated bag loader and unloader

- Fully programmable fill levels and rates

- “No-drip” valve

- Bag and cap sensors

- Automatic cap removal

- Servo-driven positive displacement pump

- Fill up to 60 bags per minute

- 1 to 24 liters

- +/- 0.3% fill accuracy

- T316 stainless steel product surfaces

- T304 stainless steel non-product surfaces

- Quick change tooling

- Clean-in-place design

- Box loader

- Customized operator interface

- Compatible with ABCO packaging lines