Automatic Pallet Dispenser

ABCO's APD reduces costs, improves efficiency, and improves your profits.

Boost Efficiency

The ABCO Automatic Pallet Dispenser (APD) is a standard option for our MPS palletizer. It is designed as an add-on to the base MPS module and is used to automate the dispensing and placement of empty pallets onto an MPS P palletizer and then transporting full pallets out of the cell.

The APD streamlines the palletizing process by ensuring a continuous and reliable supply of pallets, thus improving the efficiency of transporting pallets in and out of the MPS cell. Using an ABCO MPS palletizer and the optional APD Auto Pallet Dispenser allows you to reduce costs, improve efficiency, and improve profits.

Easy Installation with Compact Design

Our APD's compact design requires minimal floor space, requiring no disassembly for shipping and no reassembly for installation and startup. Fork truck tubes are integrated into the frame design for ease in lifting and locating the unit in your facility.

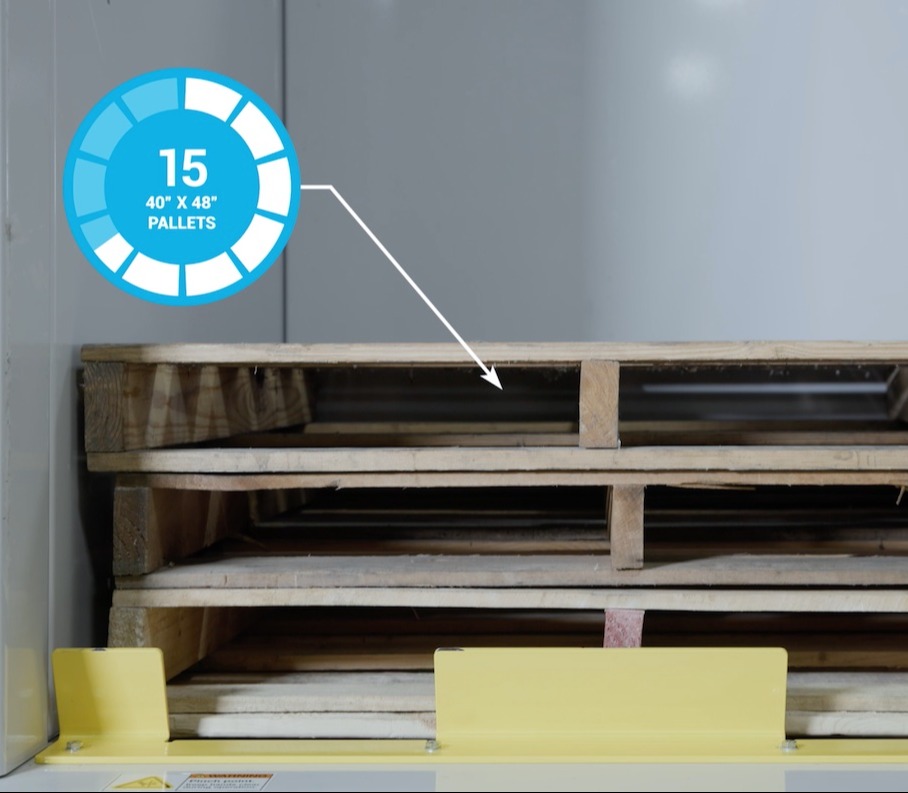

The system is 5’ wide and 7.5’ long with a height of 8’, allowing fifteen 40” x 48” GMA pallets to be accommodated at once. A dual-strand chain conveyor, which is integral to the base frame, can move up to two pallets per minute at an exit elevation of 13” top of chain.

Streamline Your Palletizing Process with Automation

The ABCO APD comes with several standard features, such as:

Uses only one utility 480V, 3-phase, 10 amp electrical hookup

No compressed air required

Automatic controls provided by the MPS cell controls

Manual controls of the pallet dispenser located on the APD

Possible integration with other automated systems