Life Science

ABCO is an industry leader in automation. Whether it is automating existing equipment or designing systems to take advantage of new technology, we are here to help you improve your bottom line.

Life Science Robot and Machine Automation

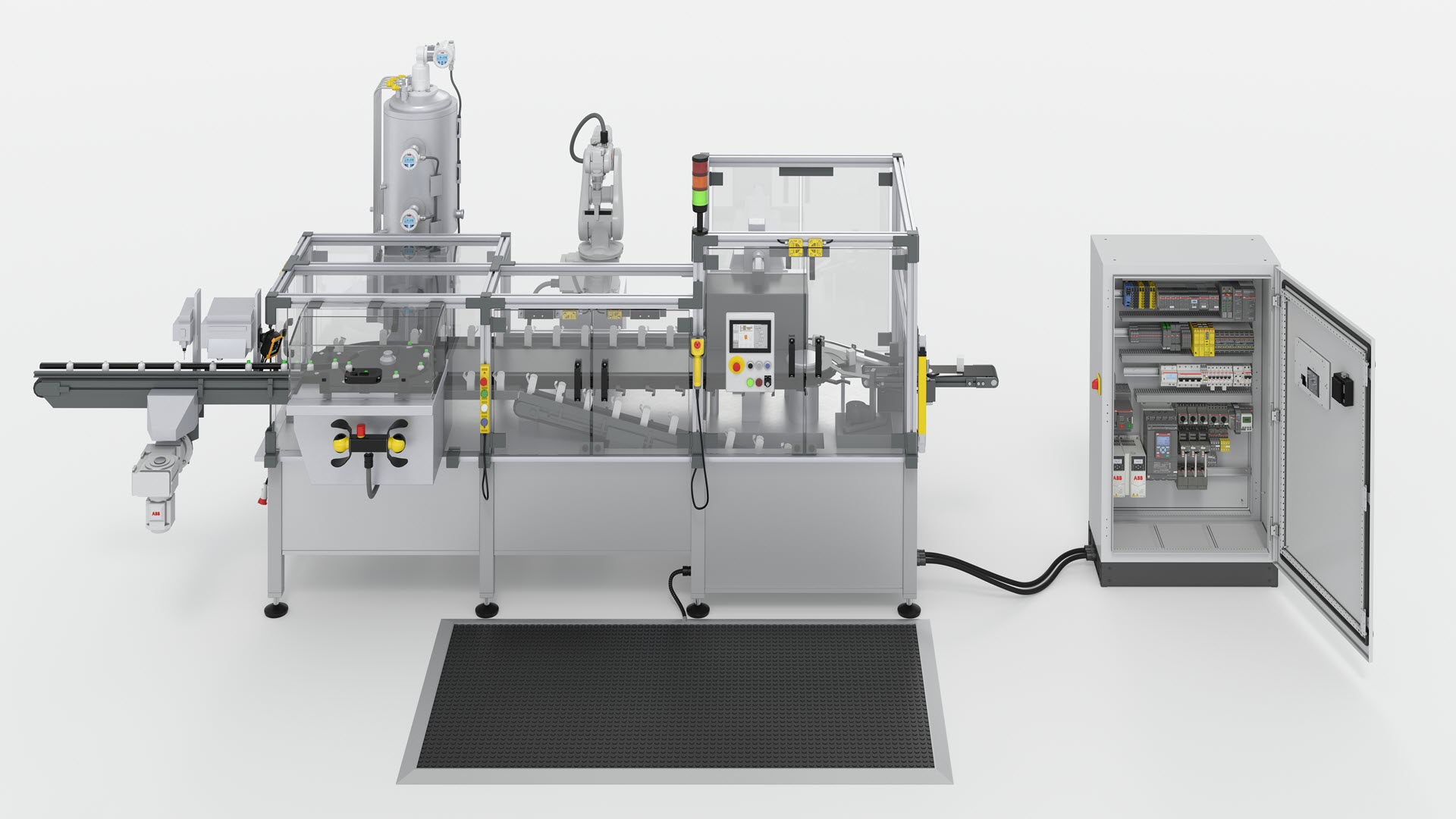

Life sciences and healthcare have never been more in the spotlight than it is right now. From pharmaceutical and medical device production, to laboratories and clean rooms, the latest ABB robotic solutions can support the human workforce and transform quality, capacity and cost of operations while improving efficiency and patient outcomes.

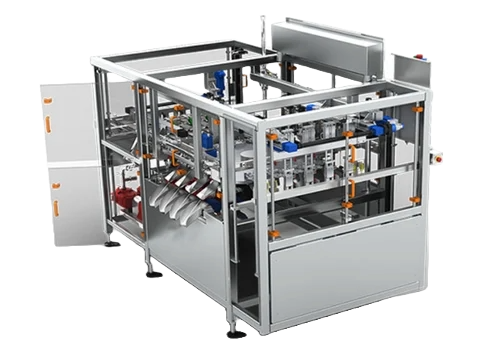

In the realms of pharmacy automation, pharmaceutical production, and the broader life sciences field, ABCO stands out by offering both single cell systems and integrated production lines designed to efficiently process, dispense, label, and package product on a large scale.

Market segments we serve

- Laboratories

- Pharmaceuticals

- Pharmacy

- Hospitals

- Cosmetics

- Medical Devices

Robotic Applications & Pharmaceutical Industries

- Robots for vaccine production

- Cold Chain robotic handling

- Freezer robot handling

- Automated pharmaceutical test kit assembly and packaging systems

- Automated pill bottle assembly, labeling, and packaging systems

- Automated syringe assembly, inspection, and preparation for packaging

- Automatic drug / medication dispensing

- Automatic syringe labeling systems

- Robotic cartoning, case packing and palletizing systems for bottles, tubes, syringes, cartons, jars, bags, and more

- Robotic pill picking, sorting and pill counter systems for automated pharmacy and medication fulfillment machines

- Robotic track and trace inspection systems for pharmacy automation

- Vertical and horizontal pharmaceutical cartoning systems

- Vial tub and tray palletizing / depalletizing systems

- And more!

ABO Contract Manufacturing for Life Science Markets

ABCO automates existing machinery or designs and build new machines to automate processes. Whether its a machine or robot cell, ABCO can create an automation solution for your business

Contract Manufacturing for Onshoring to USA

Control Panel Assembly

ISO Certification*****

ABCO Design and Build to Automate Processes

ABCO automates existing machinery or designs and build new machines to automate processes. Whether its a machine, robot cell or complete line, ABCO can create an automation solution for your business

Designs to meet your unique needs

Machine Learning / Ai for improved performance

Automation of Production Lines

Improved Safety

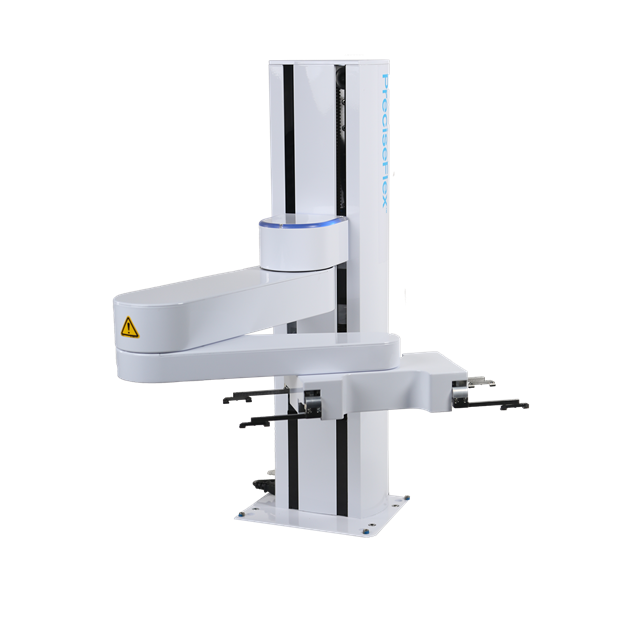

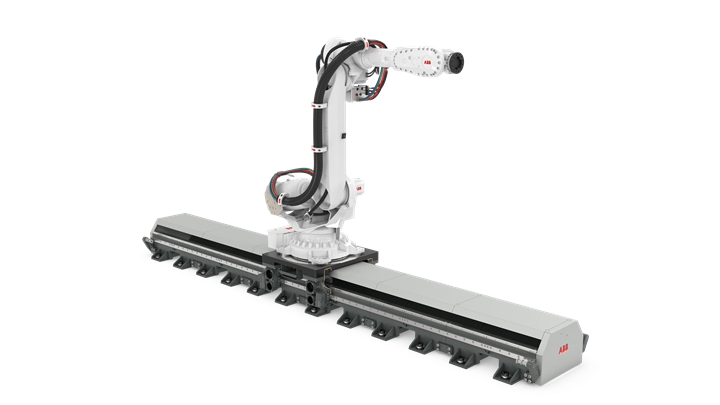

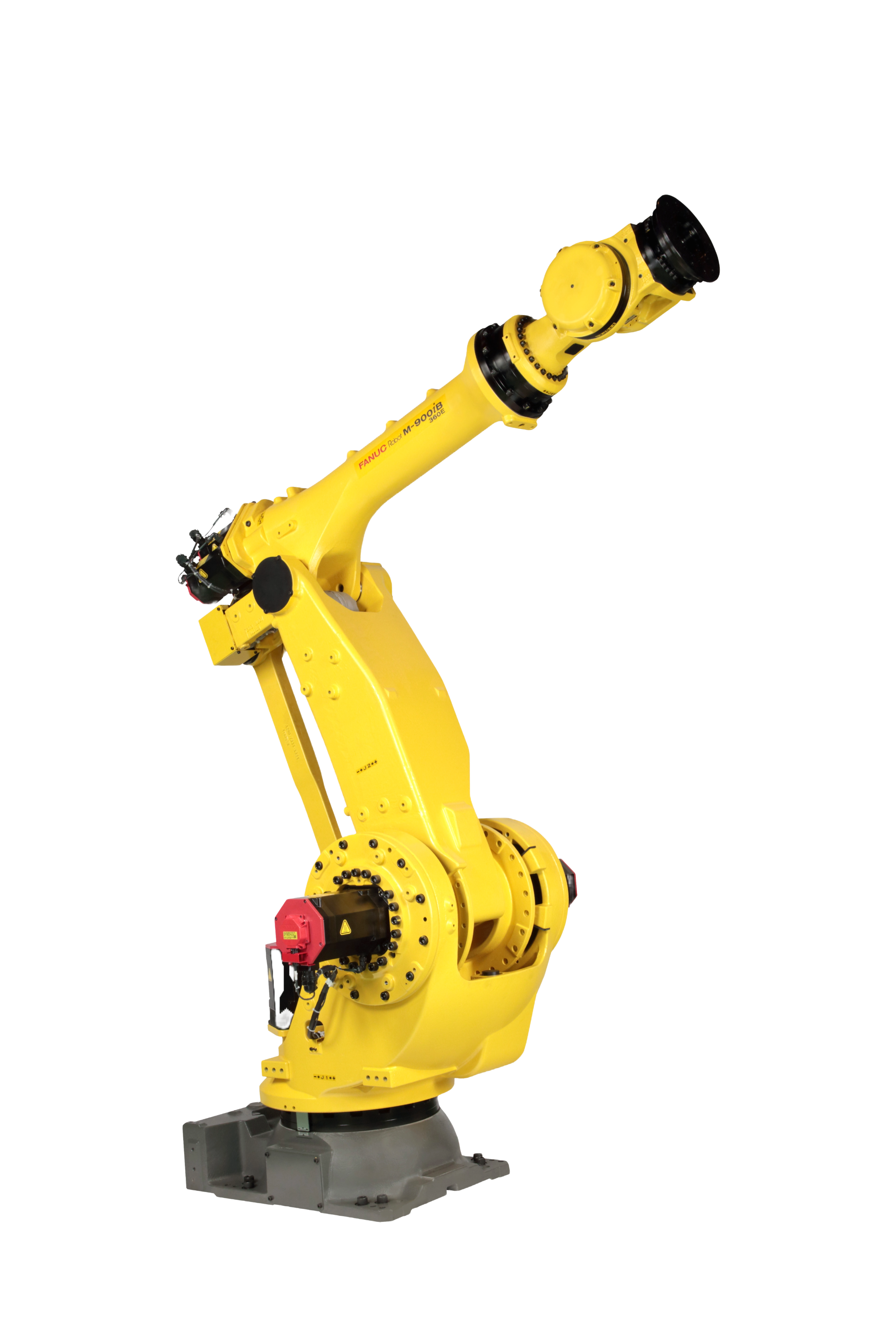

Industrial Robots & Cobots

As an authorized Integrator for several of the largest Robot manufacturers, ABCO offers many benefits to customers who have a preferred brand or are open to the best product that meets their specific needs. With decades of experience in the ABCO has standard robotic system cells and custom designs for our logistics customers. ABCO can provide comprehensive, innovative, cost-effective solutions for you..

Applications

Palletizing and Depalletizing

Case Packing

Banding and Labeling

Case Erectors

Mobile Robots

Using autonomous mobile robots in warehouse and manufacturing operations has proven to benefit numerous industries. These same industries have also benefited from using automated guided vehicle systems instead of human-operated forklifts, conveyor systems, or manual carts to move large volumes of material. To learn more about utilizing autonomous mobile robots or automated guided vehicles in your unique application, contact ABCO now.

Applications

Storage Operations

Material Handling

Production Flows

Logistics Trains

24 Hour Support

ABCO provides solutions and service to help you improve your bottom line. With the GoABCO service App, you will have 24/7 access to support for any product you purchase from ABCO. We are here as your partner before, during and long after the initial sale is complete.

Experience with Multiple Brands

ABCO has many years of experience in developing and implementing robotic systems. We can provide any form of robotics ranging from application evaluations and turnkey solutions to systems that specialize in flexible robotic work cells for accommodating short product life cycles and quick changeovers.

Benefits of Robot Automation

Factory automation fueled by robots provides many benefits to manufacturing companies, including higher productivity, lower costs, increased worker safety, and improved quality.

Lower Costs

With robotic systems, manufacturers can experience faster manufacturing times and increased efficiencies, which translates into producing more product in a timely manner. Over time those improved efficiencies lead to cost savings due to reduced waste, lower operational expenses, and decreased hands-on labor.

Employee Safety

Employees reap the bulk of the automation rewards. Robots can work in challenging environment, including hot, very cold, and very hazardous areas, so workers are to be exposed to any of those conditions. In addition, employees can be moved from performing tedious labor-intensive tasks to assignments that offer more engaging responsibilities.

Improved Quality

Additionally, manufacturers can see improved quality due to consistent product fabrication and quality control systems that use vision systems to continually check for defects.