Robotic Welding

ABCO is an industry leader in factory automation fueled by robots for manufacturing companies, leading to higher productivity, lower costs, increased worker safety, and improved quality.

Robotic Welding

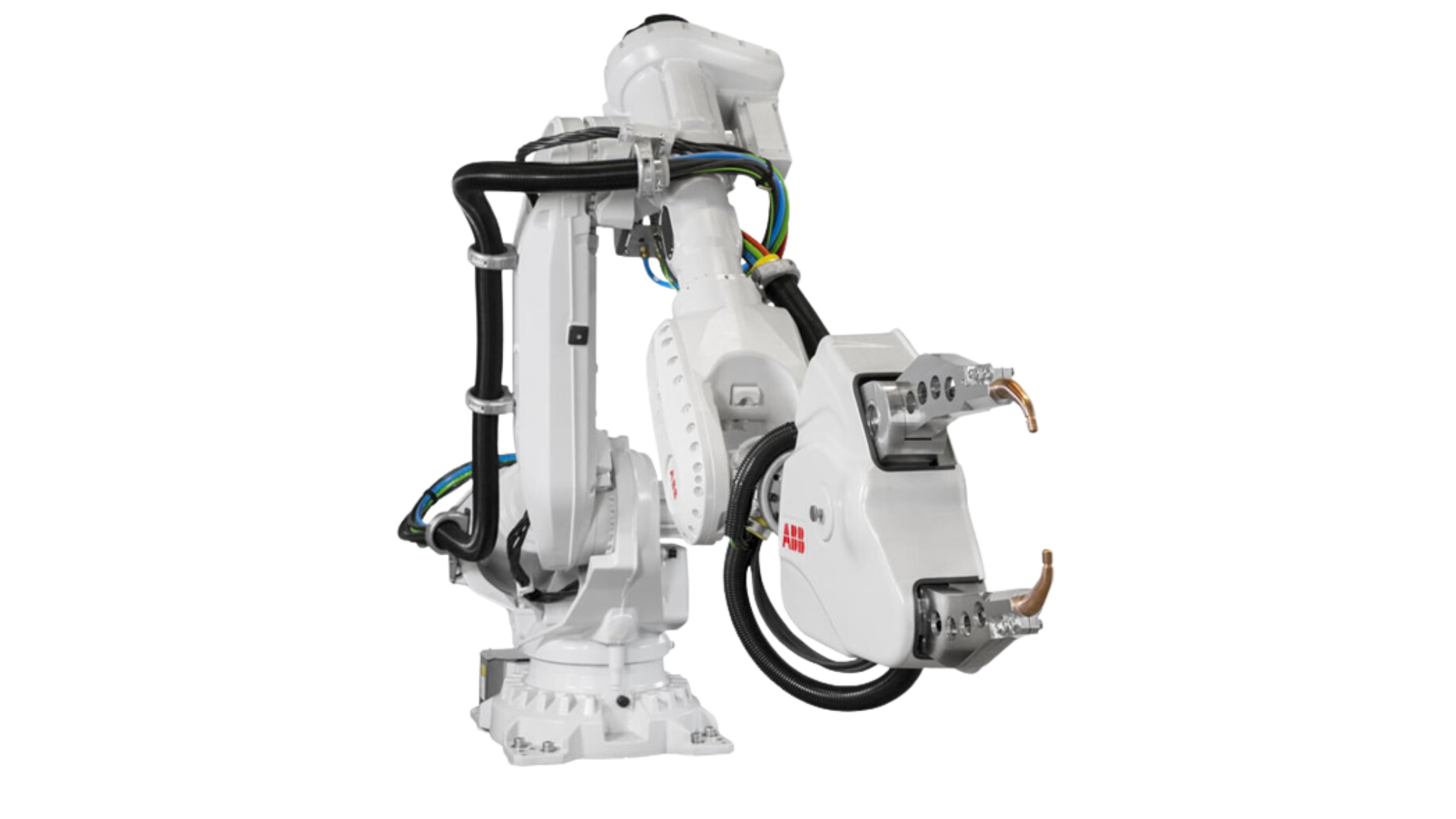

Robotic welding employs specialized industrial robots programmed for precise and consistent welding tasks, enhancing accuracy, safety, and efficiency in industrial operations. These stationary robots focus on repetitive welding tasks with high precision, forming a crucial part of broader industrial automation alongside tasks like material handling, assembly, and machine loading/unloading. By automating welding processes, robotic systems significantly increase productivity across industries. Various types of robotic welding processes are available, each programmed to efficiently manage specific welding tasks. Human welders oversee these automated processes, ensuring quality and making necessary adjustments to maintain rigorous welding standards.

Robotic Welding Use In Manufacturing

Robotic welding is pivotal in modern manufacturing, transforming welding operations by automating tasks and enhancing productivity. These advanced systems utilize specialized robots programmed to perform precise welding tasks, reducing lead times and improving safety. Particularly effective in high-volume production environments, robotic welding systems streamline operations across industries such as automotive, aerospace, heavy machinery, and electronics. By automating welding tasks, manufacturers achieve consistent weld quality, optimize resource allocation, and uphold stringent manufacturing standards.

Advantages Of Robotic Welding

Automating welding provides the following advantages:

- Speed: Robotic welding increases production speed through automated processes, saving valuable time.

- Accuracy: Precision robotic systems reduce the need for costly rework by ensuring consistent weld quality.

- Repeatability: Robots maintain uniform welding results 24/7, eliminating human variability and fatigue.

- Flexibility: Robotic welders offer versatile installation options, optimizing space efficiency in manufacturing.

- Productivity: High-speed robotic welding boosts overall output while maintaining weld quality.

- Cost Efficiency: Robotic welding lowers production costs by improving efficiency and reducing labor expenses.

- Safety: Robotic systems enhance workplace safety by minimizing exposure to hazardous welding conditions, reducing accidents in metal product industries.

Areas Where Robotic Welding Is Used

Many industries and processes use robotic welding systems:

- Automotive and parts production

- Aerospace and aviation manufacturing

- Construction and infrastructure projects

- Shipbuilding and maritime fabrication

- Heavy machinery and equipment manufacturing

About ABCO Automation

For nearly five decades, ABCO Automation has earned the trust of our customers as a go-to partner for Custom Automation Solutions, Robotic Automation, Contract Manufacturing, Standard Product Solutions and Engineering Services. An employee owned, North Carolina Based corporation, ABCO is driven by improving the profitability and quality of life for our customers and their teams through innovation and technology advancements. For more information, please contact ABCO Automation at media@goabco.com

ABCO Integrates Robots

ABCO has many years of experience in developing and implementing robotic systems. We can provide any form of robotic automation ranging from application evaluations to individual cells to turnkey solutions. ABCO will work provide you a solution based on your stated goals. We work with the best robot manufacturers in the industry and can help you pick out the right robot(s) for your needs.

Benefits of Robot Automation

Factory automation fueled by robots provides many benefits to manufacturing companies, including higher productivity, lower costs, increased worker safety, and improved quality.

Lower Costs

With robotic systems, manufacturers can experience faster manufacturing times and increased efficiencies, which translates into producing more product in a timely manner. Over time those improved efficiencies lead to cost savings due to reduced waste, lower operational expenses, and decreased hands-on labor.

Employee Safety

Employees reap the bulk of the automation rewards. Robots can work in challenging environment, including hot, very cold, and very hazardous areas, so workers are to be exposed to any of those conditions. In addition, employees can be moved from performing tedious labor-intensive tasks to assignments that offer more engaging responsibilities.

Improved Quality

Additionally, manufacturers can see improved quality due to consistent product fabrication and quality control systems that use vision systems to continually check for defects.