Carton Erection Systems

ABCO is an industry leader in factory automation fueled by robots for manufacturing companies, leading to higher productivity, lower costs, increased worker safety, and improved quality.

Carton Erection Systems

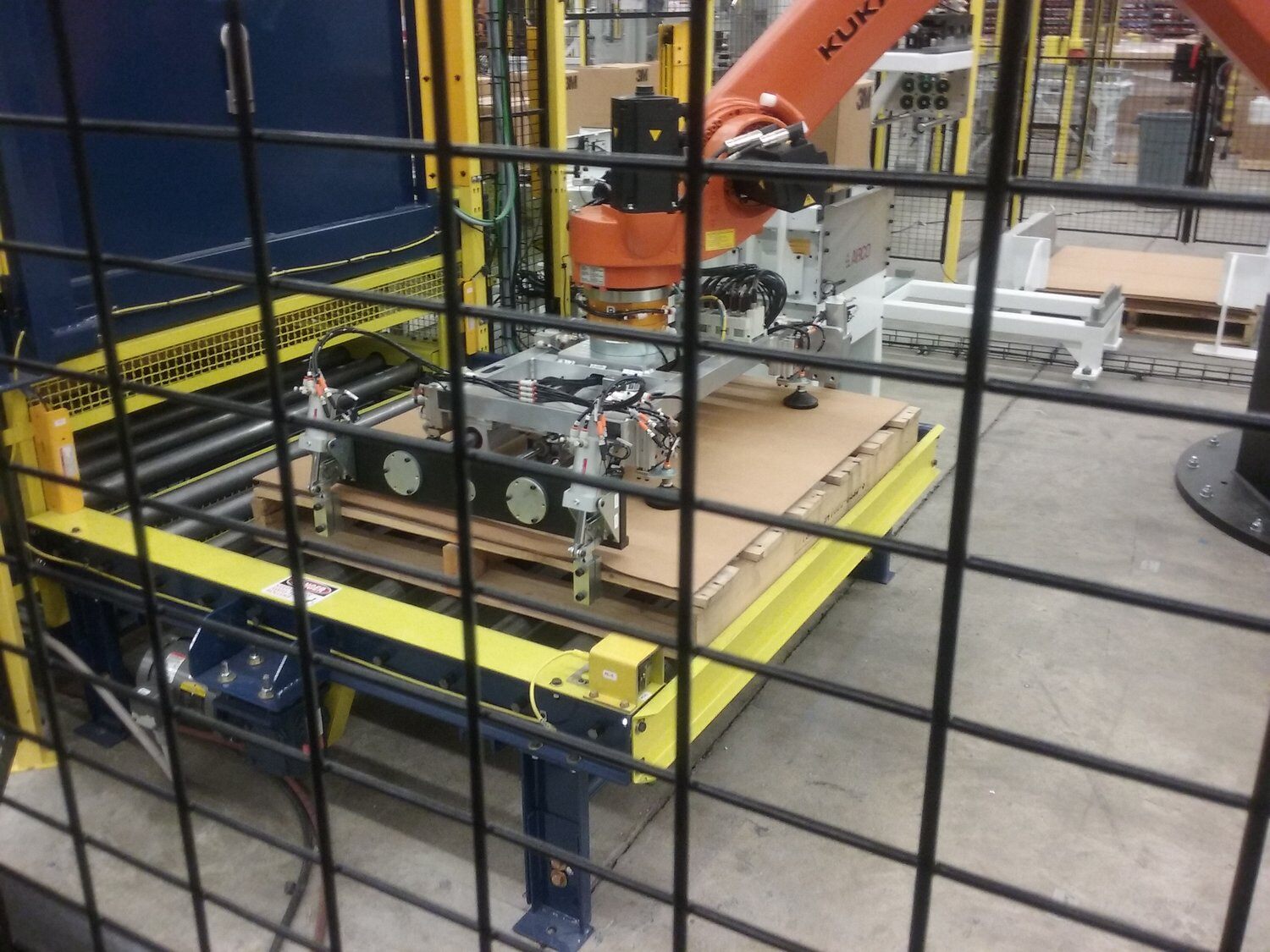

Carton erection is a packaging solution that utilizes advanced machinery to fold, form, and secure flat cardboard sheets into ready-to-use cartons or boxes. This technology significantly streamlines the packaging process by eliminating the need for manual labor, increasing efficiency, and ensuring consistency in the formation of each carton. Automated carton erectors are designed to handle a wide range of carton sizes and types, offering flexibility for different packaging needs. Equipped with precision engineering, these machines can rapidly produce large quantities of cartons, enhancing productivity and reducing operational costs.

Carton Erection Use In Manufacturing

In manufacturing, carton erection systems play a crucial role in optimizing the packaging line. Industries such as food and beverage, pharmaceuticals, and consumer goods rely heavily on this technology to maintain high-speed production and meet stringent quality standards. By integrating carton erectors into their operations, manufacturers can achieve a seamless flow from production to packaging, minimizing downtime and reducing the risk of human error. This ensures that products are consistently packaged with accuracy and integrity, ready for shipment or further processing. The adaptability of carton erection systems allows manufacturers to swiftly switch between different product lines, enhancing their ability to respond to market demands and increasing overall competitiveness.

Advantages of Carton Erection Systems:

Automating the case erection process provides the following advantages:

- Increased efficiency

- Consistency and quality

- Labor cost savings

- Flexibility and versatility

- Reduced material waste

Areas Where Carton Erection Is Used

Many industries and processes use carton erection systems:

- Beverage production and packaging

- Agricultural product packaging

- Textile and apparel packaging

- Food and snack packaging

About ABCO Automation

For nearly five decades, ABCO Automation has earned the trust of our customers as a go-to partner for Custom Automation Solutions, Robotic Automation, Contract Manufacturing, Standard Product Solutions and Engineering Services. An employee owned, North Carolina Based corporation, ABCO is driven by improving the profitability and quality of life for our customers and their teams through innovation and technology advancements. For more information, please contact ABCO Automation at media@goabco.com

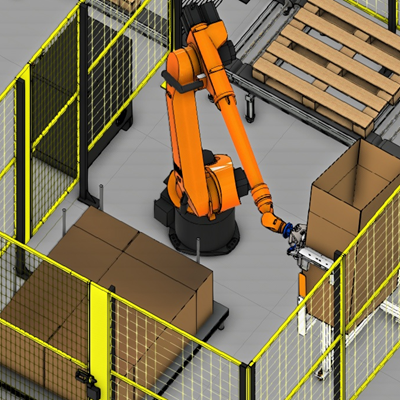

ABCO Integrates Robots

ABCO has many years of experience in developing and implementing robotic systems. We can provide any form of robotic automation ranging from application evaluations to individual cells to turnkey solutions. ABCO will work provide you a solution based on your stated goals. We work with the best robot manufacturers in the industry and can help you pick out the right robot(s) for your needs.

Benefits of Robot Automation

Factory automation fueled by robots provides many benefits to manufacturing companies, including higher productivity, lower costs, increased worker safety, and improved quality.

Lower Costs

With robotic systems, manufacturers can experience faster manufacturing times and increased efficiencies, which translates into producing more product in a timely manner. Over time those improved efficiencies lead to cost savings due to reduced waste, lower operational expenses, and decreased hands-on labor.

Employee Safety

Employees reap the bulk of the automation rewards. Robots can work in challenging environment, including hot, very cold, and very hazardous areas, so workers are to be exposed to any of those conditions. In addition, employees can be moved from performing tedious labor-intensive tasks to assignments that offer more engaging responsibilities.

Improved Quality

Additionally, manufacturers can see improved quality due to consistent product fabrication and quality control systems that use vision systems to continually check for defects.