Bag in Box Filling

ABCO is an industry leader in factory automation fueled by robots for manufacturing companies, leading to higher productivity, lower costs, increased worker safety, and improved quality.

-1.png)

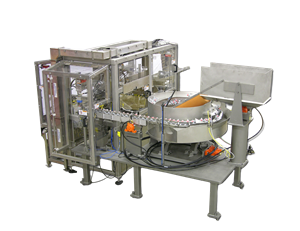

Bag in Box Liquid Filling

Bag in Box (BiB) filling systems are essential for efficiently packaging liquids into flexible bags contained within rigid boxes. These automated systems streamline the filling process, ensuring precise measurement and sealing of products such as beverages, chemicals, and food ingredients. Our advanced BiB filling solutions integrate cutting-edge technology to meet diverse production needs, enhancing operational efficiency and product integrity.

Bag in Box Use In Manufacturing

Bag in Box packaging plays a crucial role across various manufacturing sectors by offering versatile and efficient storage and dispensing solutions. From food and beverage industries, where it ensures freshness and extends shelf life, to chemical and pharmaceutical sectors, where it safely stores and dispenses sensitive liquids, BiB systems optimize production processes while maintaining product quality and safety.

Advantages Of Bag in Box Filling

Automated Bag in Box filling provides numerous advantages:- Efficiency: Streamlines filling operations, reducing labor costs and enhancing throughput.

- Versatility: Handles a wide range of liquids and viscosities, from juices and sauces to industrial chemicals.

- Quality Assurance: Ensures precise filling volumes and seals, minimizing product waste and contamination risks.

- Space Optimization: Compact footprint and scalable designs accommodate varying production environments.

- Environmental Benefits: Reduces packaging waste with recyclable materials and eco-friendly designs.

Areas Where Bag in Box Is Used

Many industries and processes use Bag in Box systems:

- Beverage production and packaging

- Dairy product packaging

- Industrial chemical packaging

- Personal care and household product packaging

- Paints and coatings packaging

Whether it is a complete line or a single filler, ABCO has decades of experience with proven technologies so our any of the BIB Liquid Fillers we offer provide:

- Increased production capacity

- Enhanced yields and profits through improved precision and accuracy

- Increased productivity with loading and unloading automation

- Clean environment from drip-free filling, sanitary design, and clean-in-place system

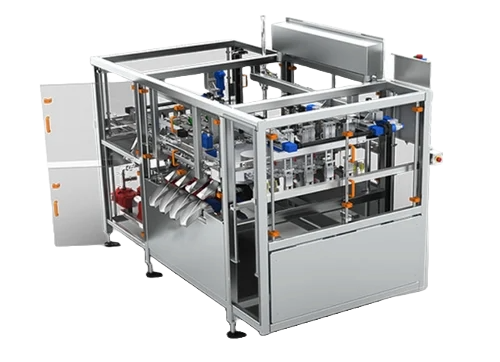

Complete Production Line

If you need a complete production line, ABCO can help. Many of our customers have asked us to provide a turnkey solution which included:

- Carton Erector

- BIB Liquid Filler

- Case Sealer and Labeler

- Palletizer

- Shrink wrapping

- Conveyors

Whatever your needs, ABCO is here to help, Please contact us today if you need assistance with a BIB Liquid Filling project

ABCO Integrates Robots

ABCO has many years of experience in developing and implementing robotic systems. We can provide any form of robotic automation ranging from application evaluations to individual cells to turnkey solutions. ABCO will work provide you a solution based on your stated goals. We work with the best robot manufacturers in the industry and can help you pick out the right robot(s) for your needs.

Benefits of Robot Automation

Factory automation fueled by robots provides many benefits to manufacturing companies, including higher productivity, lower costs, increased worker safety, and improved quality.

Lower Costs

With robotic systems, manufacturers can experience faster manufacturing times and increased efficiencies, which translates into producing more product in a timely manner. Over time those improved efficiencies lead to cost savings due to reduced waste, lower operational expenses, and decreased hands-on labor.

Employee Safety

Employees reap the bulk of the automation rewards. Robots can work in challenging environment, including hot, very cold, and very hazardous areas, so workers are to be exposed to any of those conditions. In addition, employees can be moved from performing tedious labor-intensive tasks to assignments that offer more engaging responsibilities.

Improved Quality

Additionally, manufacturers can see improved quality due to consistent product fabrication and quality control systems that use vision systems to continually check for defects.

.png)