Automating Dispensing Systems

ABCO is an industry leader in factory automation fueled by robots for manufacturing companies, leading to higher productivity, lower costs, increased worker safety, and improved quality.

Automating Precision Dispensing & Placement Applications

Automated dispensing and placement systems significantly enhance manufacturing processes by enabling the rapid and consistent application of various fluids and materials. These systems, driven by sophisticated control software and robotics, allow for high-speed and precise operations without requiring continuous operator involvement. This automation not only boosts productivity but also offers substantial time and cost savings by minimizing the risks of workplace injuries, reducing the need for extensive equipment training, and lowering overall labor demands.

ABCO Automation excels in delivering advanced, high-accuracy dispensing and placement solutions tailored to our customers' needs. Our systems emphasize precision, speed, and accuracy to ensure maximum output and versatility across different industries. By incorporating robotic dispensing technologies, we streamline production processes, enhance efficiency, and reduce costs simultaneously.

Automated Dispensing Use In Manufacturing

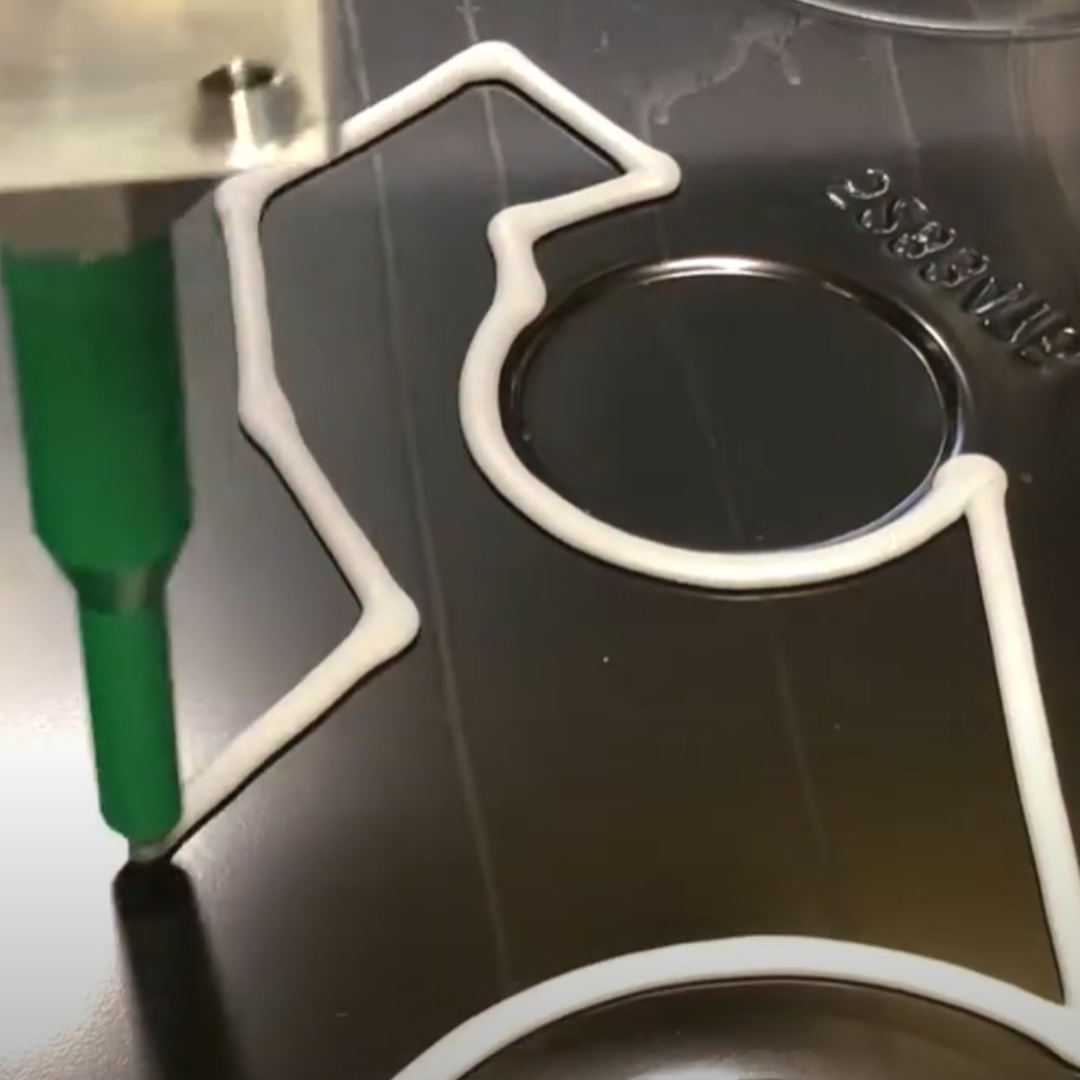

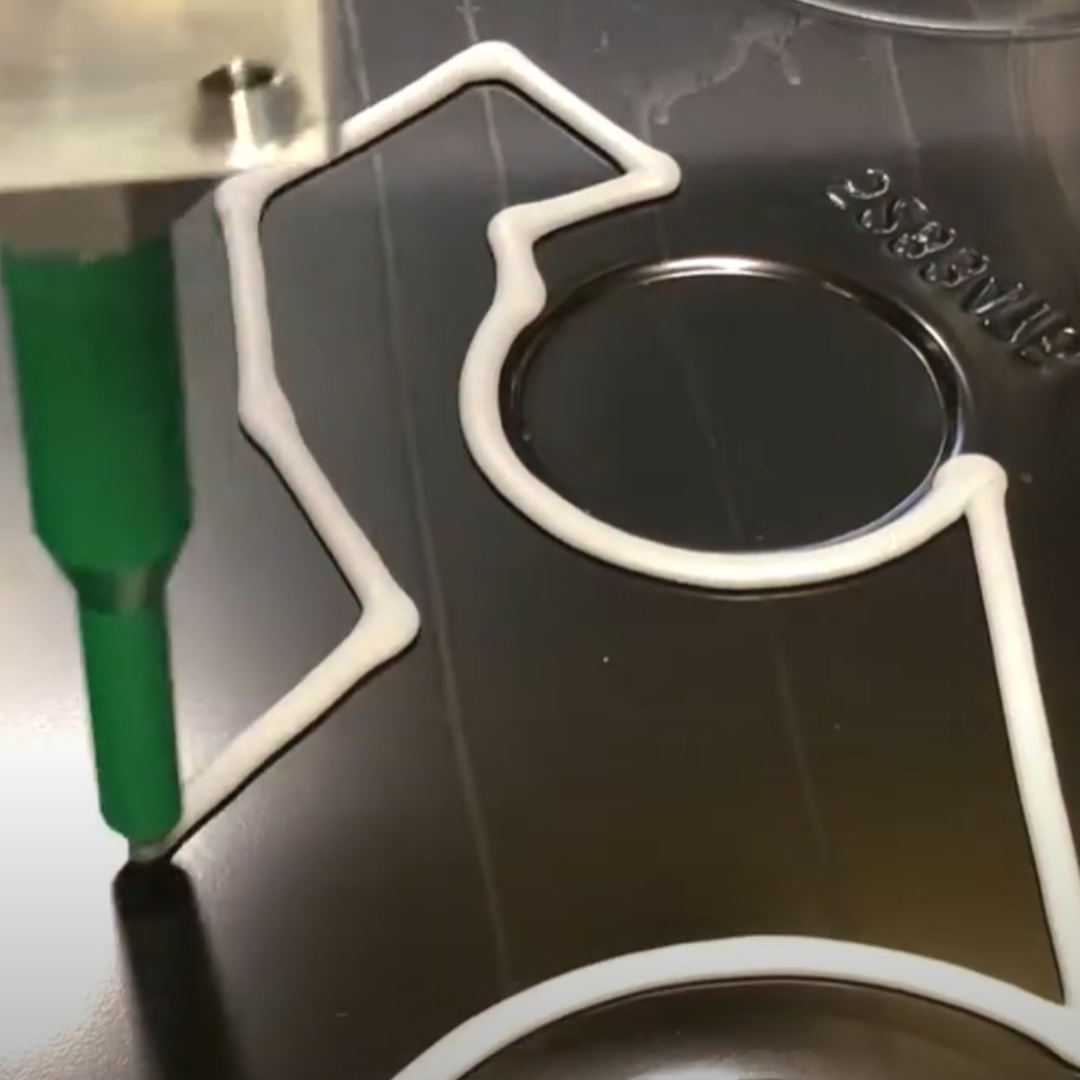

Many manufacturing and assembly processes rely on the high efficiency and accuracy of robotic dispensing and placement systems, whether in batch or inline dispensing operations. These automated systems are crucial for the precise application of various fluids, including oils, coatings, sealants, solder paste, grease, and adhesives. The integrated software in these systems provides advanced motion control, enabling the intuitive programming of fluid arcs, patterns, stripes, or dots on multiple planes.

Automated dispensing systems often incorporate weight-scale verification to enhance quality control. This feature ensures better product consistency by reducing variability in each manufactured product or batch. The system digitally records the weighing process and its results, which can be displayed for regulatory reviews or product releases, providing full traceability.

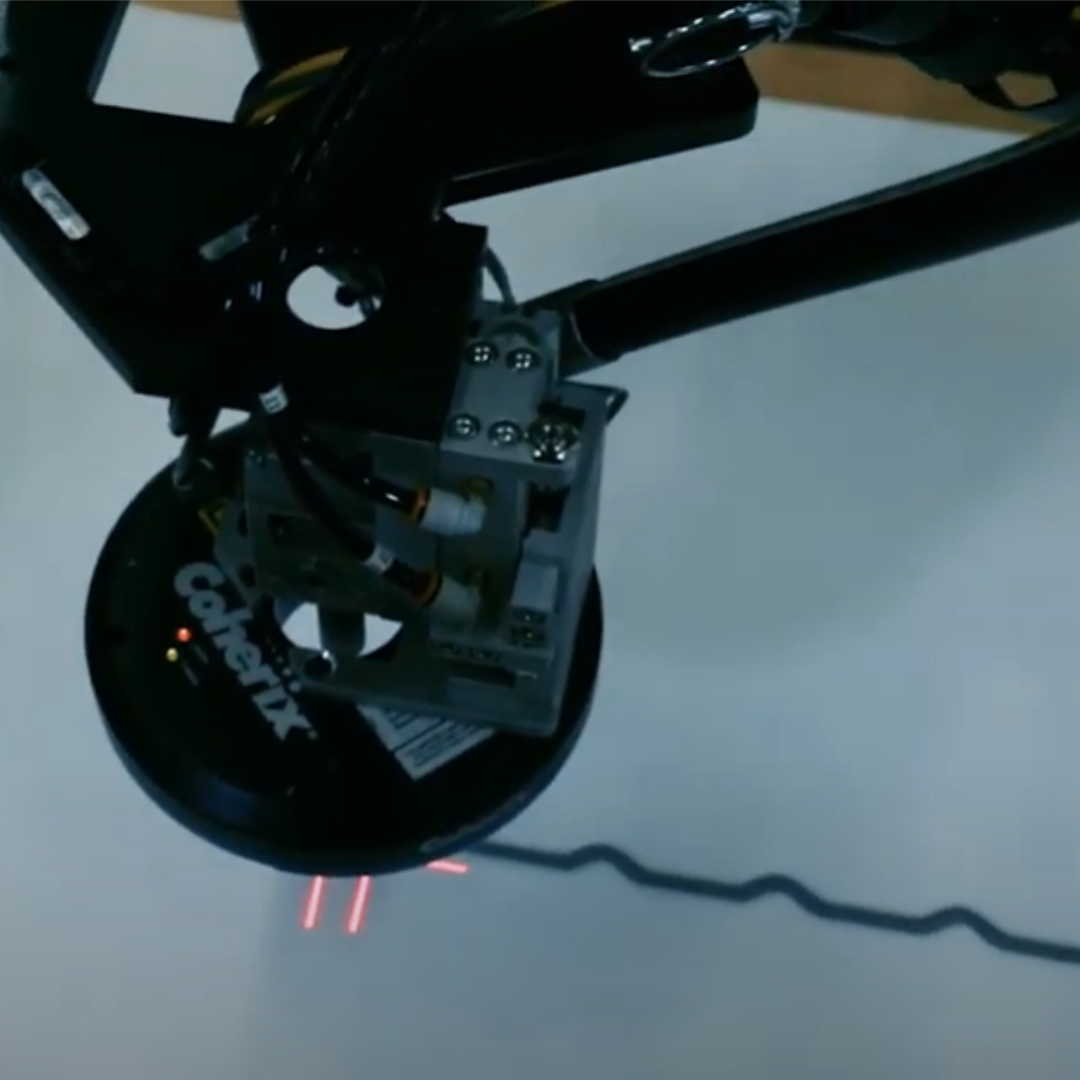

Additionally, integrating vision systems with automated dispensing and placement systems enhances their functionality. Vision systems offer on-screen previews of dispensing paths and can be installed on appropriate axes for robotic systems, including 3-axis and 4-axis robots. This integration further increases the precision and efficiency of the dispensing processes, making them even more reliable and versatile.

Advantages Of Automating The Dispensing Process

Automating material dispensing and placement provides the following advantages:

- Reduced labor demand and safety costs

- Reduction in human error and variance

- Increased productivity and accuracy

- Applicable to many material types

- Increased repeatability

Areas Where Automated Dispensing Is Used

Many industries and processes use automated dispensing and placement systems:

- Automotive and parts production

- Food and consumer product packaging

- Manufacturing and assembly processes

- Healthcare equipment manufacturing

- Pharmaceuticals and medicine packaging

ABCO Automation integrates manufacturing systems that utilize material dispensing as part of the assembly process for multiple customers. If your manufacturing or assembly application is dependent on dispensing, contact us today.

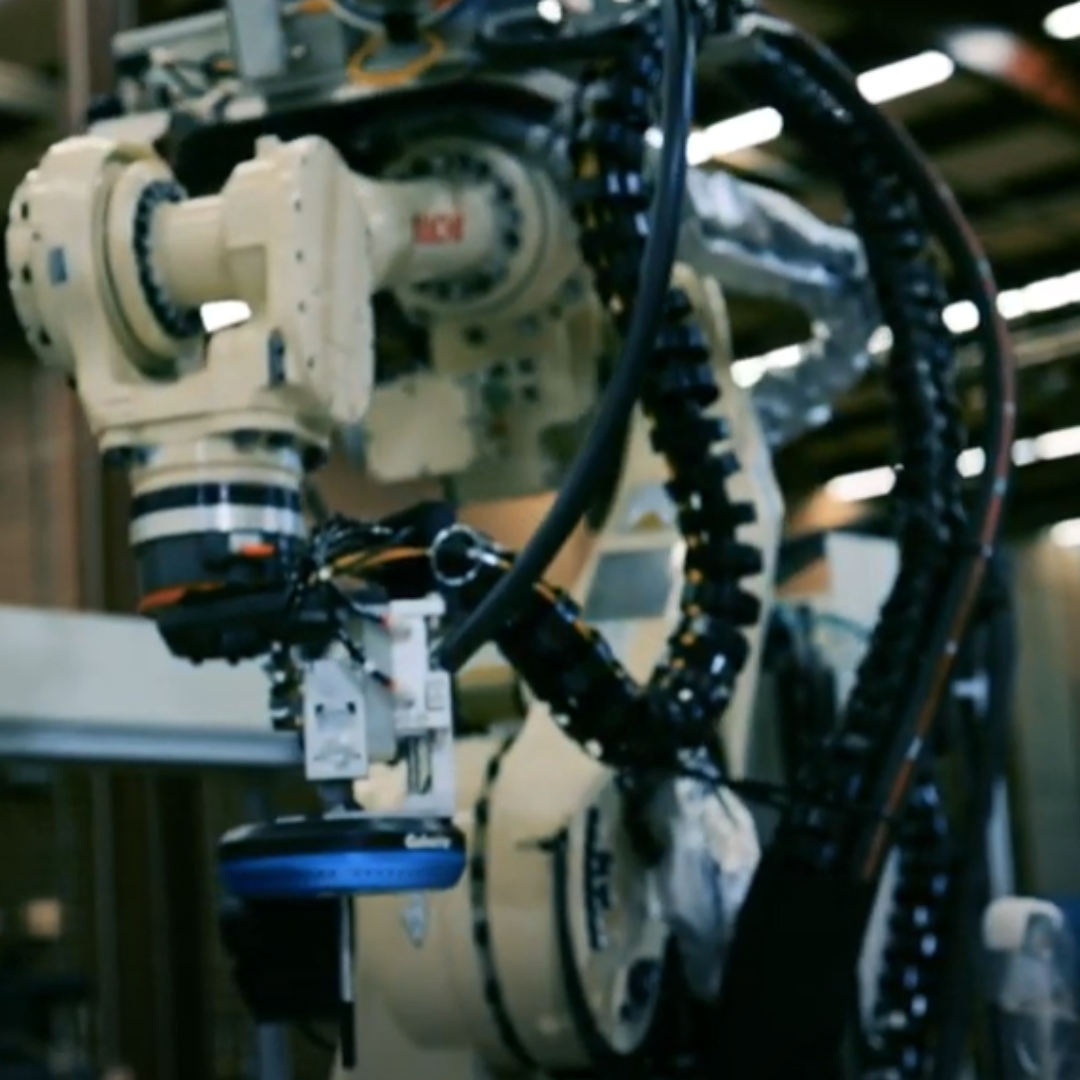

ABCO Integrates Robots

ABCO has many years of experience in developing and implementing robotic systems. We can provide any form of robotic automation ranging from application evaluations to individual cells to turnkey solutions. ABCO will work provide you a solution based on your stated goals. We work with the best robot manufacturers in the industry and can help you pick out the right robot(s) for your needs.

Benefits of Robot Automation

Factory automation fueled by robots provides many benefits to manufacturing companies, including higher productivity, lower costs, increased worker safety, and improved quality.

Lower Costs

With robotic systems, manufacturers can experience faster manufacturing times and increased efficiencies, which translates into producing more product in a timely manner. Over time those improved efficiencies lead to cost savings due to reduced waste, lower operational expenses, and decreased hands-on labor.

Employee Safety

Employees reap the bulk of the automation rewards. Robots can work in challenging environment, including hot, very cold, and very hazardous areas, so workers are to be exposed to any of those conditions. In addition, employees can be moved from performing tedious labor-intensive tasks to assignments that offer more engaging responsibilities.

Improved Quality

Additionally, manufacturers can see improved quality due to consistent product fabrication and quality control systems that use vision systems to continually check for defects.