Mechanical Engineering Services

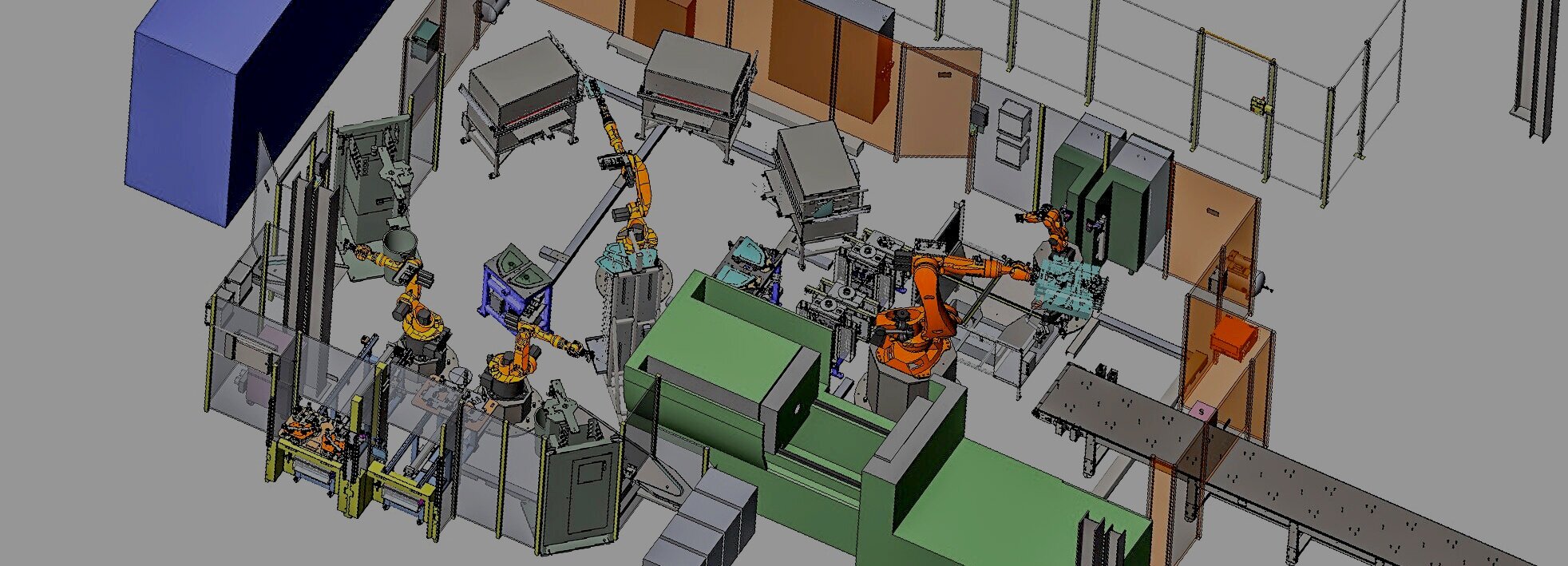

The design process ranges from overall conceptual engineering to detailed design to machine and system programming. To manage mechanical designs, our mechanical engineers work hand in hand with project managers, electrical engineers and customers. With 45+ mechanical and electrical engineers on staff, we’re poised to design build a solution, product or assembly for any manufacturing environment and any system type.

ABCO design engineers are well-versed in SolidWorks 3D Software. Through this dynamic software package, we are not only able to create mechanical and electrical designs, we have the ability to:

Execute thorough concept evaluations

Create e-drawings for client collaboration

Generate drawings for instruction and maintenance manuals

Produce manufacturing drawings and electrical schematics

Perform a finite element analysis for determining potential part issues

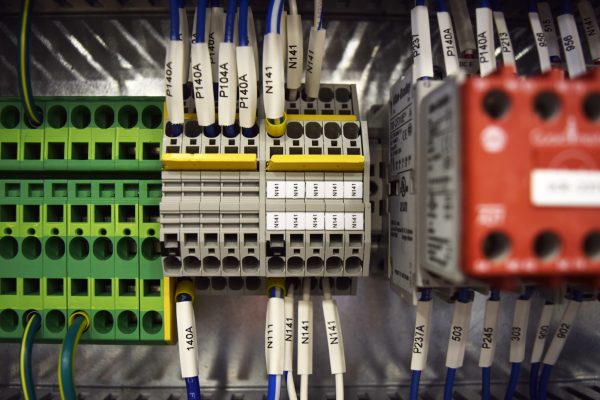

Control System Engineering

ABCO Automation’s control system engineering capabilities span individual machine controls to large network manufacturing controls systems with MES interface. ABCO control systems engineers analyze a project's requirements as well as the mechanical design of the machine in order to create a controls system that will function in the desired manner. Our process includes:

Assessing safety risks

Defining data structure layout and data flow models

Developing a functional description of the automation solution

Selecting the physical communication media, network architecture & protocols

Control scheme, alarms, HMI, and reports using the established rules to guide development and programming

Software Development & Programming

Our processes for development and programming of controls systems include:

-

Develop HMI, database, and reporting functions in accordance with the design documents to the functional requirements

-

Review configuration and programming using defined practices in order to establish compliance with functional requirements

-

Develop control configuration or programming

-

Implement security methodology to mitigate loss and risk

-

Designing a testing plan to execute appropriate testing relative to functional requirements

-

Assembling required documentation and user manuals created during the development process in order to transfer essential knowledge to our clients and end users

ABCO's control system engineering team provides extensive client support during testing and debugging of the systems and on-site support for start-up and training.

Brand Experience

Our team of controls engineers, technicians, and designers are well-rounded with all major controls suppliers and robot manufacturer programming such as:

- Rockwell Automation

- Siemens

- Mitsubishi

- Beckhoff

- B&R

- Omron

- ABB Robots

- Staubli Robots

- Fanuc Robots

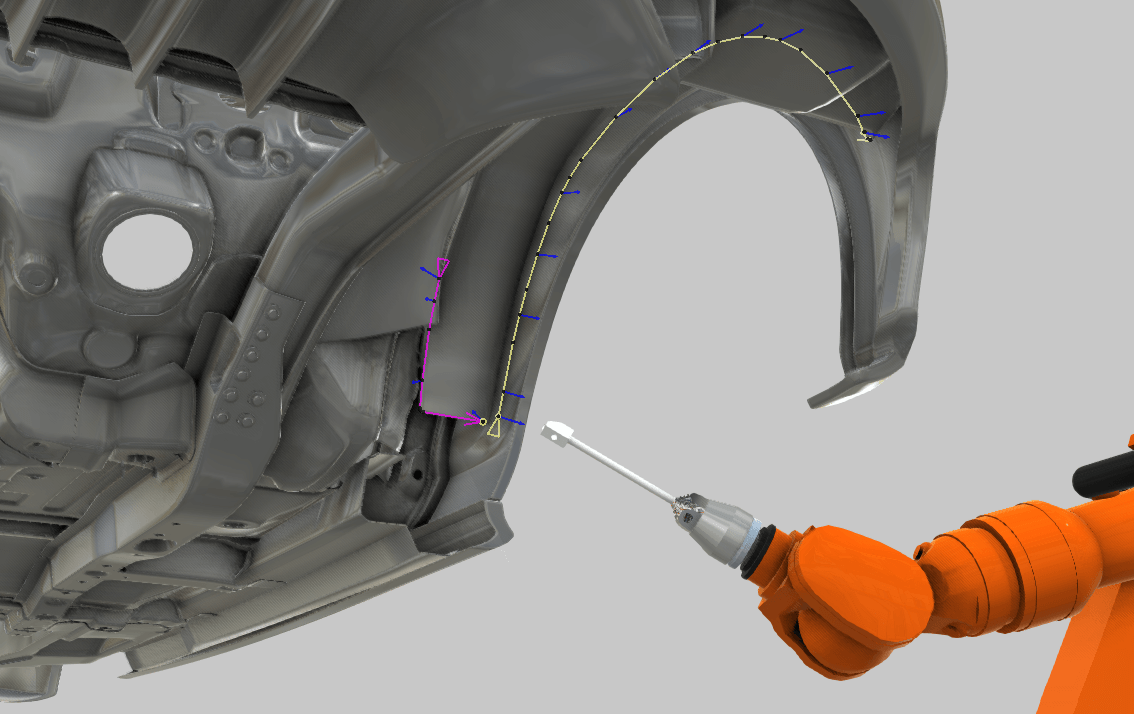

- KUKA Robots

- Kawasaki Robots

- Nachi Robots

- Brooks

- Denso

- Yaskawa

- Epson

- Universal Robots

- AVEVA

- Parker

- Banner

- Fanuc IR Vision

- Cognex Vision

- Keyence Vision

Simulation Software

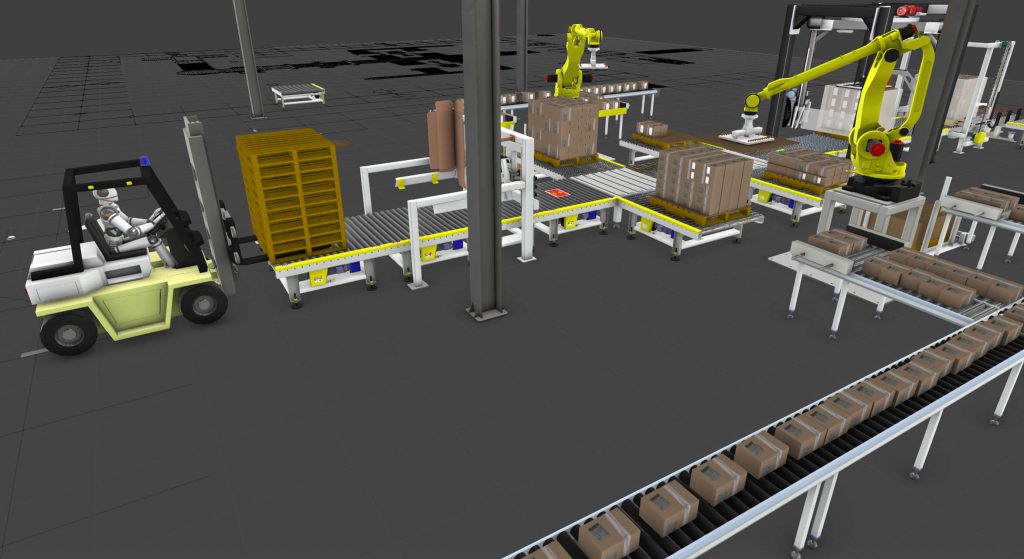

From concept and throughout the design process, a key component of ABCO Automation’s offering is the use of simulation software. With the programs, we can see design flaws, test different operations, and make adjustments before committing to a final design. Here are some of the benefits of adding simulations to our design process:

Reduce critical mistakes and oversights

Minimize downtime and speed up implementation

Cost savings by avoiding process and equipment mistakes

Gain predictable performance, get better outcomes

Improve team collaboration, eliminate knowledge gaps

Documentation

All system design documentation includes control panel layouts, bills of material, electrical schematics, operations manuals, preventative maintenance checklists and spare parts list are available to our customers through the GoABCO Service App and Customer Portal

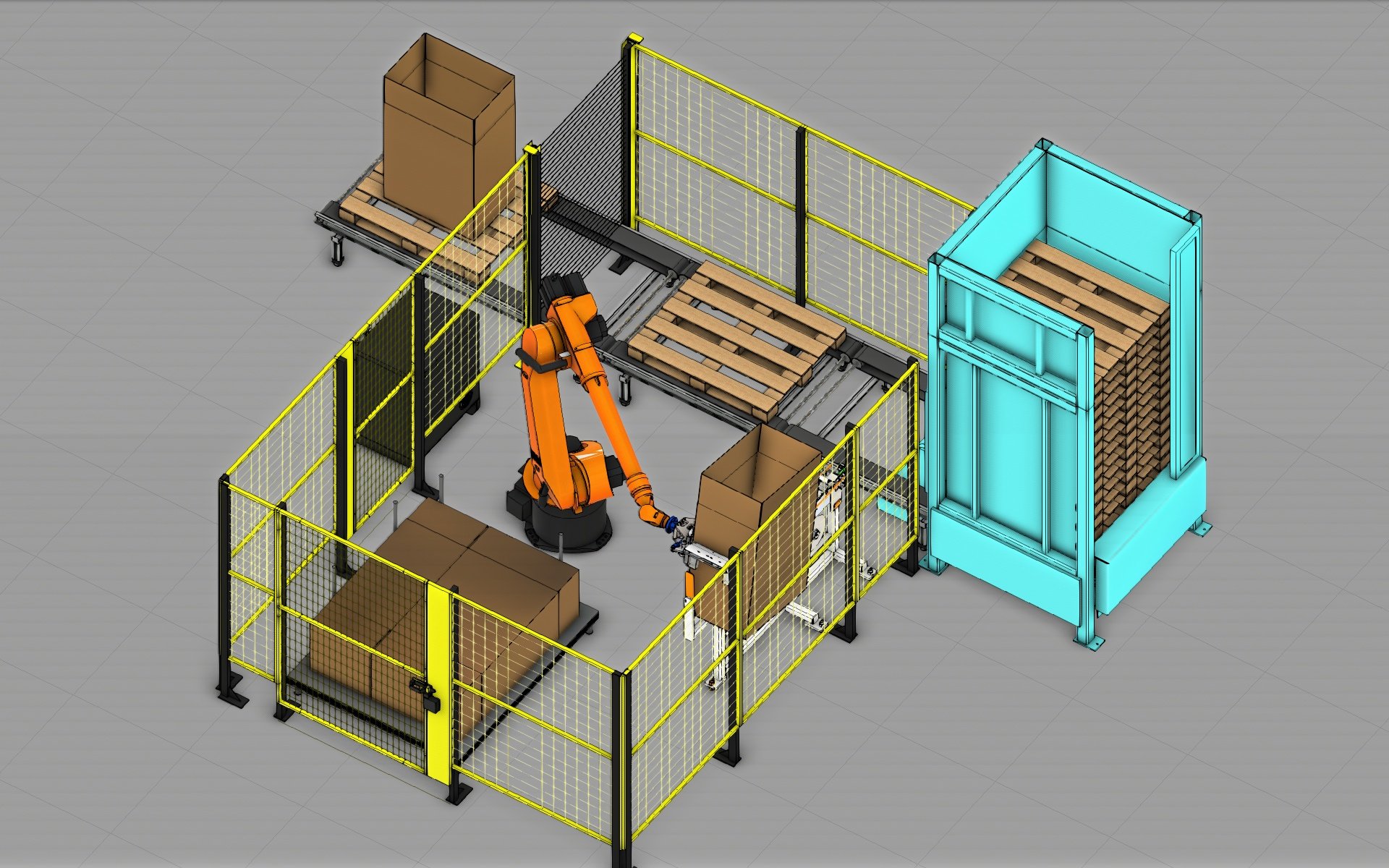

Material Handling Systems

Whether a stand-alone cell or comprehensive production line, ABCO can design and build an automated material handling system to fit virtually any application. We have extensive experience with all facets of the material handling process including: robotic part selection, part transfer, packing, palletizing, and loading/unloading.

Inspection & Testing Systems

From stand-alone test stations to online 100 percent inspection systems, ABCO designs and builds specialized inspection and testing equipment to enhance the inspection process, provide a production line overview, and identify/classify defects. Our strengths in machine vision, control systems, and customized part handling enable us to deliver quality turnkey solutions.

.jpeg?width=350&height=150&name=image-asset%20(1).jpeg)

Vision Systems Solution for Manufacturing

ABCO Designs and Builds a wide range of vision solutions which help detect product defects, monitor production lines, guide assembly robots, and recognize barcodes or optical characters as well as track, sort and identify parts. A vision system can help improve quality, eliminate errors, while lowering costs.