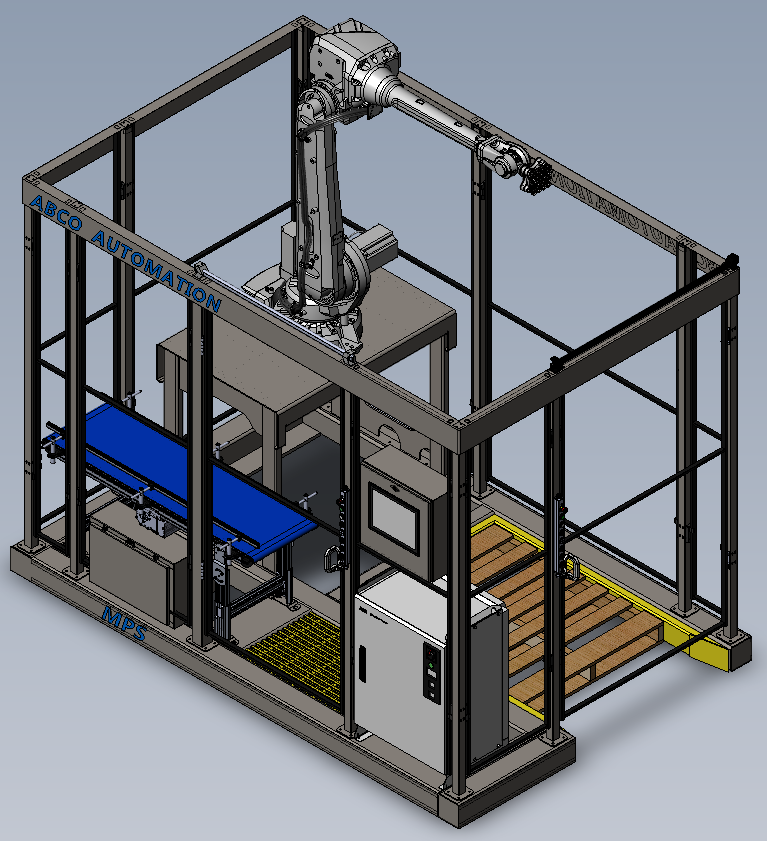

Modular Palletizing System

ABCO offers two solutions for your palletizing needs: our Modular Palletizing System or a Custom Palletizing System designed and built by our experienced team. Whether it is a single cell or complex system, ABCO has Palletizing option to fit your needs, budget and timeframe.

Modular Palletizing System

ABCO's cost-effective, MPS Palletizing System allows you to choose pre-engineered options to add to the MPS Base Unit for your specific application.

Features of ABCO's MPS Palletizing System

Base Footprint: (LW) 137”x 85”

Min. Case Size (LWH) 3”x 5”x 1”

Max Case Size (LWH) 20” x 18” x 18”

Ready to Ship: 6 week to 8 week***

Single power drop installation

Low energy consumption controls & drives

Built in connectivity for future use

Service and Maintenance App

Group One Options

ABCO has pre-engineered many options for the MPS Palletizer. Choose what you want and add to your modular system.

MPS Palletizer Option Examples:

Pallet Feeder

Pallet Stacker

Pallet Crowder

Infeed Crowding

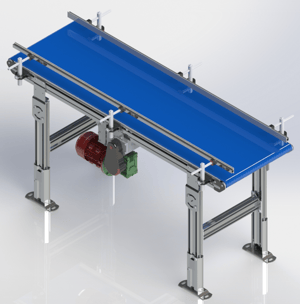

Infeed/Outfeed Conveyor

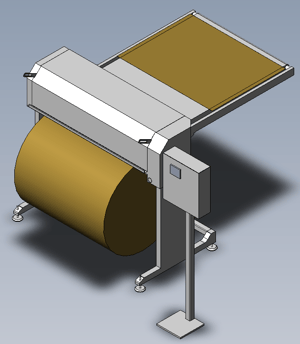

Rotary Stretch Wrapper

Drag Chain Conveyor

Group Two Options

These engineered options for ABCO's MPS Palletizer System are related to controls and maintenance.

Remote Performance Monitoring

Remote Re-Programming

Machine Learning Controls

Vision Inspection Systems

Best-in-Class Palletizing Robots

ABCO palletizing systems feature leading robotic brands. Our MPS Palletizer Systems offers two standard choices and our Custom Engineered Palletizing Systems can come with the robot of your choice

MPS Palletizing System features ABB or Staubli robots as standard options

Custom Engineered Solutions: ABB, FANUC, KUKA, STAUBLI and more